British Design, American Power.

Our magnetic drills are designed in Sheffield, England and built to the highest specifications. By working with our expert product development team, we’re able to launch exciting new drills and introduce cutting edge technologies into the market.

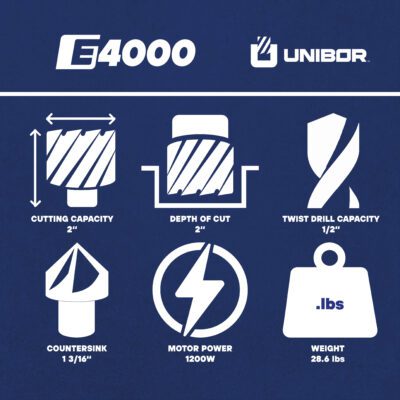

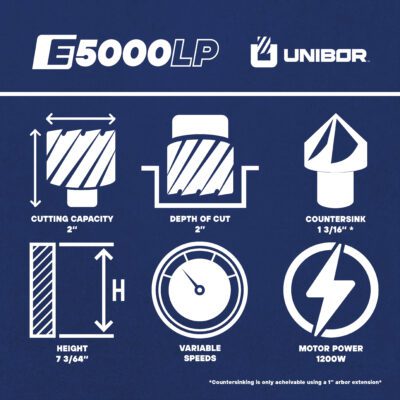

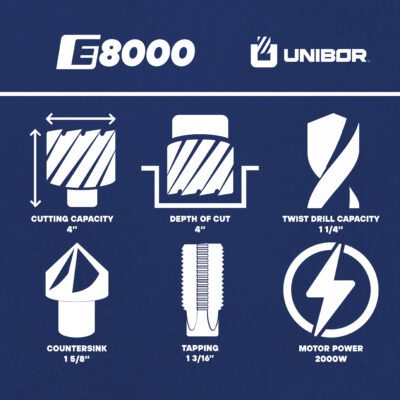

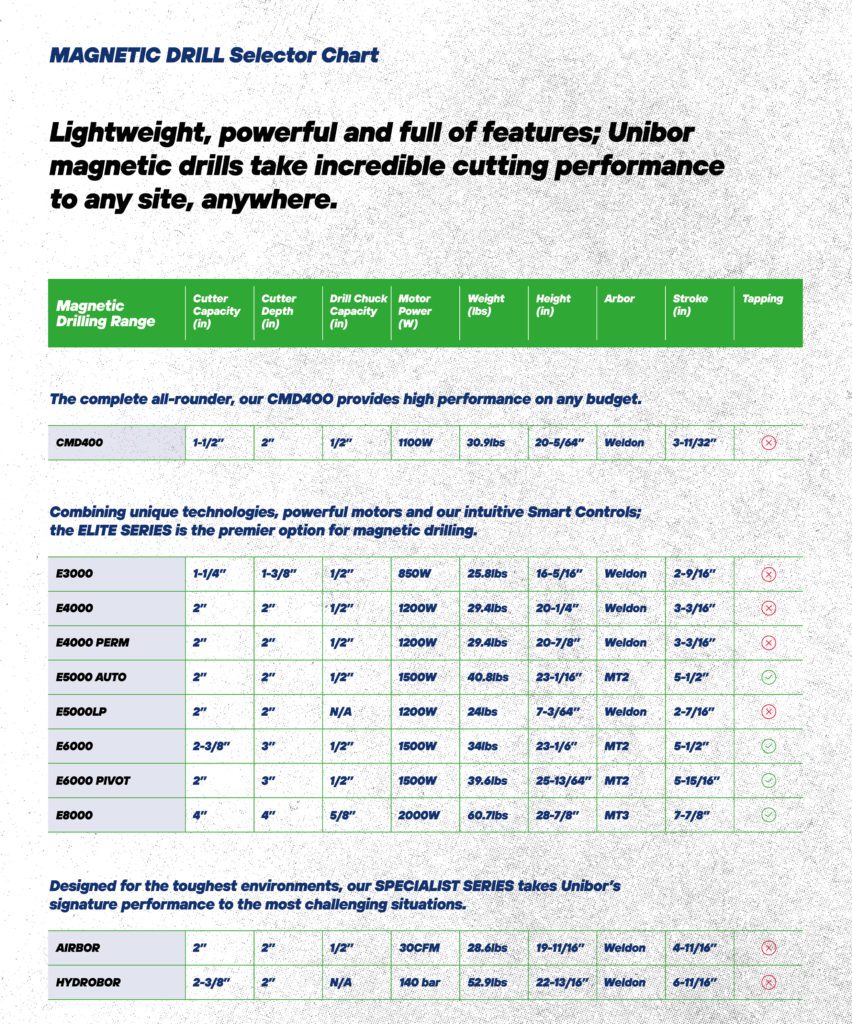

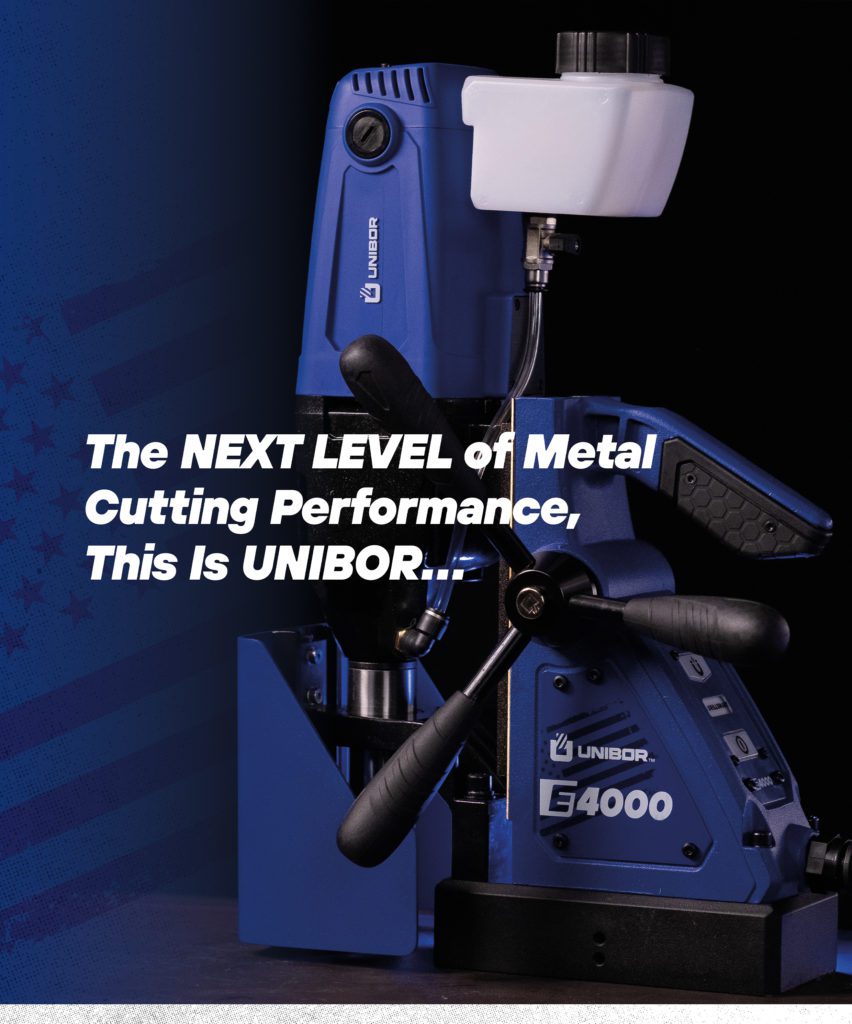

The flagship Unibor range, the Elite Series, combines unique technologies with market-leading performance. Featuring Smart Controls, a range of specialist designs and our signature DrillSmart technology, the Elite Series has everything needed for the toughest jobs and the biggest projects.

Budget-Friendly Performance, For Any Project.

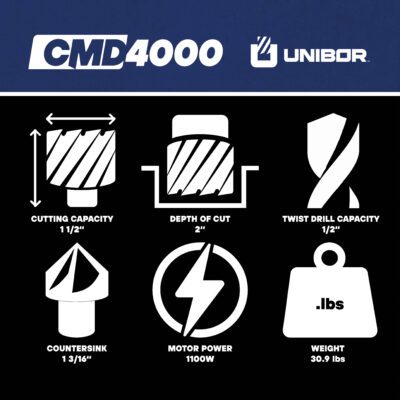

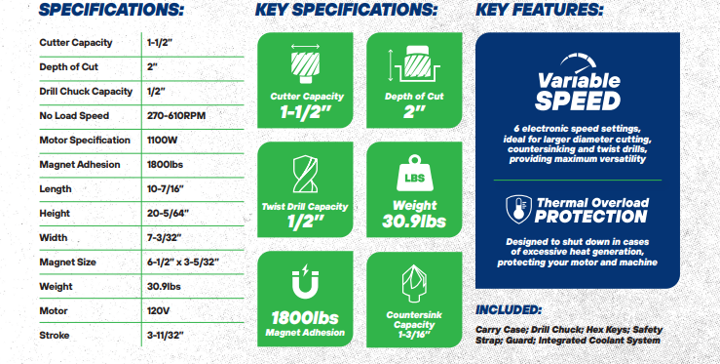

Alongside our world-class Professional Range, we also produce the Commando Range, our cost-effective option for budget friendly performance on any project. With solid, reliable power and variable speeds, the CMD400 is ideal for countersinking and general drilling applications.

Mag Drill FAQ’s

-

What is a mag drill used for?

A mag drill is used for drilling holes in steel and other metals. It uses a magnetized base to bind to the target surface, allowing for the magnetic drill to cut holes in various different locations with ease.

Due to their flexibility and portability, magnetic drilling machines are used in industries across the world, from steel fabrication to oil/gas drilling, as well as construction and DIY.

-

How deep can a mag drill cut?

Mag drills can cut to a range of depths, with some heavy-duty machines capable of cutting to 100mm in depth. Cutters also determine how deep a mag drill can cut, with different cutters designed to different depths of cut.

-

When would you use a mag drill?

A mag drill should be used in any situation requiring large hole cutting projects that involve metal cutting, numerous holes and need the portability a mag drill offers.

-

What is a magnetic drill bit?

Magnetic drill bits are most often referring to annular cutters, used in a process called ‘core drilling’.

They are designed to drill into tough metals without wearing out, the most commonly-used magnetic drill bit, the annular cutter, is designed to cut the periphery of the hole and remove the core, otherwise known as the ‘slug’.

-

Can you use a mag drill on pipe?

You can use a mag drill on pipe, some mag drills are specifically designed for this type of work, using our PermaMag technology to adhere to extremely thin and uneven surfaces.

-

Do I need to use a safety chain with my mag drill?

A safety chain/strap is one of the key features and should always be used in conjunction with a mag drill to ensure both user safety and proper machine application.

-

Will a mag drill work upside down?

Mag drills are perfect for drilling at difficult angles, including upside down, sideways etc. This is due to their powerful magnetic base, making them a safe option for these difficult jobs.