Annular Cutter FAQ’s

-

Can you re-sharpen annular cutters?

Yes, annular cutters can be re-sharpened with an annular cutter sharpener. This means that, once dull, an annular cutter can be repurposed reused, therefore furthering the cost-effective efficiency of the product.

-

What is a pilot pin?

When using an annular cutter, a pilot pin is a large nail-like object that must be used. It performs three critical functions:

- Determines the center of the hole

- Allows coolant to flow down the slug and into the cutting teeth.

- At the end of the cut, ejects the slug. Pilots fly through the cutter’s center.

As the hole is drilled, they retract into the mag drill arbor. Pilot pins are extremely durable and can be used with a variety of cutter sizes.

-

What causes dull or broken annular cutters?

A slow feed rate is the most common cause of broken or prematurely dull cutters, using a slow feed rates will significantly shorten your cutter’s life . Using a constant, firm feed pressure throughout the cut will improve performance and extend tool life. Ideally, the user should the drill motor spinning and the cutter pulling long chips from the hole. Search for a ‘bird’s nest’ near the cutter to double-check proper operation of the cutter.

-

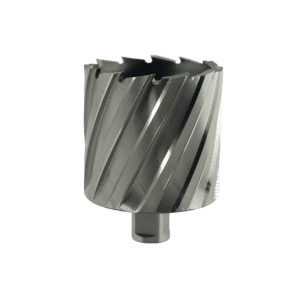

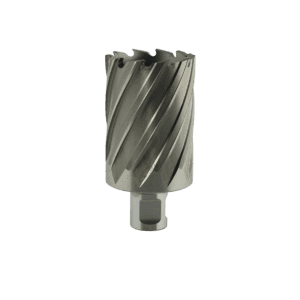

What is the anatomy of an annular cutter?

An annular cutter is made up of the following components: #

Cutting Teeth: Different angles are referred to as ‘geometry’, this performs the actual cutting.

Flats: This component holds the cutter rigid during use.

Flutes: Pulls chips from the hole during operation.

Shank: Allows fitting the annular cutter into the chuck, often used with mag drills.