These helpful tools are ideal for creating a professional finish on a metal product, able to produce a countersink hole for a screw head to fit flush against the surface. In this blog, we’ll discuss countersink drill bits and their benefits:

What is a countersink drill bit?

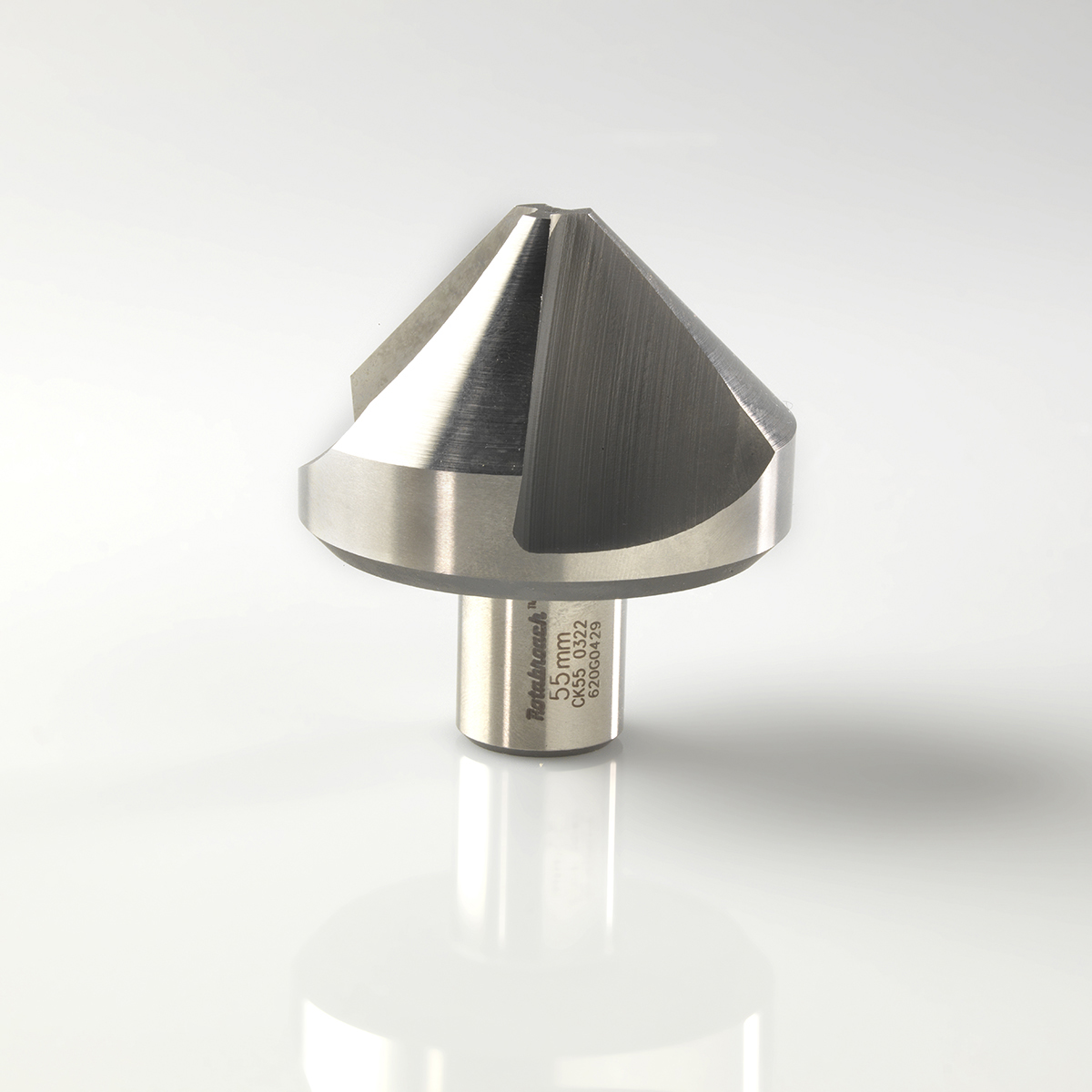

A countersink is a conical hole cutting tool that is typically used to allow the head of a countersunk screw or bolt to fit flush with the surface of the surrounding material. They feature a cylindrical shape and conical tip, and are used when a concave surface is desired for a screw or bolt head. Countersinking can also help to prevent the head of the screw or bolt from being damaged or stripped when it is tightened.

Countersink bits are often referred to as counterbores, amongst other names.

What are countersinks made from?

A Countersink bit is generally produced from High-Speed Steel (HSS) or similar metals. These materials are able to withstand the high temperatures and abrasive forces that are generated during the hole drilling process, whilst also being able to maintain a sharp edge for a long time.

Additionally, countersink bits are often coated with a hard, durable finish to help protect them from wear and tear, as well as to make them easier to clean. Some specialist countersink bits may also be made from other materials, such as cobalt or titanium, depending on the intended use for the tool.

What can countersinks cut through?

Countersinks are typically used to cut through a variety of materials, including various different metals, plastics and composites. The specific materials that a countersink can cut through will depend on the type of material the drill bit is made from, as well as its size and design. In general, however, countersinks are capable of cutting through a wide range of different materials.

What are the benefits of countersinking?

There are several benefits to using countersinks in a project. Some of the main benefits include:

- A finished, professional look: Using a countersink to create a conical hole for a countersunk screw or bolt allows the user to fit a screw flush to the surface.

- Improved holding power: A countersunk hole allows the head of the screw or bolt to sit properly and securely in the material, which can help to prevent the screw or bolt from becoming loose over time.

- Increased durability: Using a countersink can help to prevent the head of a screw or bolt from being damaged or stripped when it is tightened, which can increase its overall durability as well as the finish quality.

- Ease of use: Countersinks are typically easy to use, and they can save time and effort when compared to other methods of creating a countersunk hole.

Overall, using countersinks can help to improve the quality and durability of a project, as well as making the process more streamlined and efficient.

Should I use a countersink with a mag drill?

Yes, it is in fact recommended to use a countersink cutter with a mag drill as it can make the process of creating a countersunk hole far easier and more efficient, this is because the mag drill can hold the countersink securely in place while it is being used thanks to the drill chuck. However, it is important to choose the right type of countersink for use with a mag drill, as not every countersink bit is designed to be used with this type of tool.

Some countersinks are specifically designed for use with mag drills, featuring a shank that is compatible with the chuck of a mag drill. It is also important to make sure that the countersink is properly secured in the mag drill before use, and also to use the tool according to the manufacturer’s instructions to ensure safety and avoid damaging both the countersink and the material being drilled.

When should you countersink a hole?

Countersinking a hole is necessary when a flat or slightly concave surface is desired for the head of a screw or bolt, and when the screw or bolt head needs to be flush with the surface of the surrounding material.

As well as this, countersinking can be beneficial when a screw or bolt needs to be tightened securely, as the countersunk hole can help to prevent the head of the screw or bolt from being damaged or stripped. This gives more longevity and durability to the finished product. Overall, countersinking is a useful technique to consider whenever a screw or bolt needs to fit flush to the surface of a project.

Can you produce a countersink hole with a regular drill bit?

It is possible to use a regular drill bit to create a countersunk hole, but it is not the most effective or efficient method. Regular drill bits are not designed to create countersunk holes, and they may not produce a clean, uniform hole that is the correct shape and size for a countersunk screw or bolt. Additionally, using a regular drill bit to countersink can be difficult and time-consuming, as the user must carefully control the angle and depth of the hole to ensure that it is the correct shape and size. Therefore, countersink drill bits are the ideal tool for fitting a screw head flush to the surface, rather than a traditional drill bit.

How fast should a countersink drill bit run?

The speed at which a countersink should run will depend on the material being drilled and the size and design of the countersink. Generally speaking, however, a countersink drill bit should run at a relatively high speed in order to cut efficiently and produce a clean, uniform hole. For most materials and countersink sizes, a speed of around 1,500 to 2,000 RPM is a good starting point, however the exact speed will depend on the specific conditions of the drilling operation. It is important to refer to the equipment’s safety documentation or other details for the countersink and the material being drilled, and to adjust the speed as necessary to produce the ideal results.

Should you countersink before tapping?

It is generally recommended to countersink a hole before tapping it. Tapping is the process of creating threads in a hole, and it typically involves using a specialist tool called a tap to cut the threads into the material. Countersinking the hole before tapping can make the process easier and more efficient, as it creates a conical hole that allows the tap to start cutting threads more easily. Additionally, countersinking can help to prevent the tap from becoming damaged or stripped, as the countersunk hole allows the tap to sit securely in the material.

Overall, countersinking before tapping can improve the quality and durability of the threads, as well as making the tapping process easier and more efficient.

What is a self-countersinking screw?

Self-countersinking screws are screws that have a specialised design, allowing them to create their own countersunk hole as they are being screwed into the workpiece. This can make the process of creating a countersunk hole faster and easier, as the user does not need to use a separate tool, such as a countersink, to create the hole. Self-countersinking screws typically have a tapered or conical shape design on the end of the screw, allowing them to cut a hole that is the correct shape and size for the screw head as the screw is being tightened.

This can make it easier to achieve a finished, professional look, and it can also help to prevent the screw head from being damaged or stripped when it is tightened. However, it is important to choose the right size and type of self-countersinking screw for the specific application, as not all self-countersinking screws are the same.

What are the different types of countersink drill bits?

There are several different types of countersink bits, each of which is designed for specific applications and materials. Some of the most common types of countersinks include:

- Single-flute countersinks: Single-flute countersinks have a single cutting edge, and they are typically used for drilling softer materials such as wood, plastic, or composites.

- Multi-flute countersinks: Multi-flute countersinks have multiple cutting edges, and they are typically used for drilling harder materials such as metal.

- Adjustable countersinks: Adjustable countersinks have a mechanism that allows the user to adjust the angle of the countersink, which makes them suitable for creating countersunk holes at different angles.

- Tapered countersinks: Tapered countersinks have a conical shape that allows them to create a tapered hole, which is useful for creating holes that are wider at the surface and narrower at the bottom.

- Chamfer mills: Chamfer mills are similar to countersinks, but they have a fluted design that allows them to remove material more efficiently and produce a smoother finish.

Overall, the type of countersink that is best for a specific application will depend on the material being drilled, the angle of the countersunk hole, and the desired finish which ideally avoids protruding screw heads.

How do I use a countersink drill bit?

To properly countersink screws using a countersink bit, first, make sure that the cutting tool is securely fastened in a drill or drill press. Next, mark the desired location on the workpiece where the hole will be drilled. Sometimes it is a good ideal to drill a pilot hole, if you are not expanding an existing hole, which is simply a pre drilled hole to guide the countersink drill bit. Using a low speed and steady pressure, slowly guide the countersink into the workpiece, cutting a conical hole as you go. It is important to use a steady, even pressure to ensure that the hole is clean and free of burrs or rough edges.

Once the hole has been drilled to the desired depth, carefully remove the countersink from the workpiece and smooth any rough edges with a file or sandpaper. If all of these steps are completed properly, the screw head should sit flush with the surface, countersunk screws should not appear above the surface of the material.

What are different types of countersunk screws?

Countersunk screws are a type of screw that has a conical head with a flat top and a tapered underside. This design allows the screw to be inserted into a countersunk hole in a workpiece, with the flat top of the screw sitting flush with the surrounding surface.

These screws are commonly used in a variety of applications, including woodworking, metalworking, and construction. Some common types of countersunk screws include flat head screws, oval head screws, and round head screws. These screws are available in a range of sizes and materials, including steel, brass, and aluminium, to suit a variety of applications.

Can I countersink sheet metal?

Yes, it is possible to countersink sheet metal. However, because sheet metal is a relatively thin and delicate material, it can be more challenging to countersink than deep drilling into thicker, more robust materials. When countersinking sheet metal, it is important to use a low speed and steady pressure to prevent the cutting tool from tearing or damaging the material. It is also important to use a countersink designed for use with sheet metal, as regular countersinks may not provide the necessary cutting performance or accuracy. It isn’t possible to drill a hole deep into sheet metal, therefore countersink holes can be a challenge.

Additionally, it may be necessary to use a lubricant, such as cutting oil, to reduce friction and heat during the cutting process. As with any cutting operation, it is also important to use appropriate safety equipment, such as gloves and eye protection, to prevent injury

How can I countersink safely?

Countersinking, like any other method of drilling holes, can be dangerous if not done properly. To ensure safe and effective countersinking, it is important to follow these safety tips:

- Always wear appropriate personal protective equipment, such as gloves, safety glasses, and ear protection, to prevent injury.

- Make sure that the countersink is securely fastened in the drill or drill press before beginning the cutting operation.

- Use a low speed and steady pressure when guiding the countersink into the workpiece to prevent tearing or damaging the material.

- Avoid applying excessive force to the countersink, as this can cause the cutting tool to become damaged or break.

- Use a lubricant, such as cutting oil, to reduce friction and heat during the cutting process.

- Keep your hands and fingers away from the cutting area at all times to prevent injury.

- Regularly check the condition of the countersink and replace it if it becomes dull or damaged.

- Always unplug the drill or drill press before making any adjustments or changing the countersink.

By following these safety tips, you can help to ensure that your countersinking operation is safe and successful.

No Related Posts